Wow! The competition is just one month away! We are now perfecting the boat. Sorry for having no updates for the past few weeks!

As of now, we had the metal frame in place to hold the boat together, and had tested the boat for seaworthiness.... oops, I mean lake-worthiness..... haha...

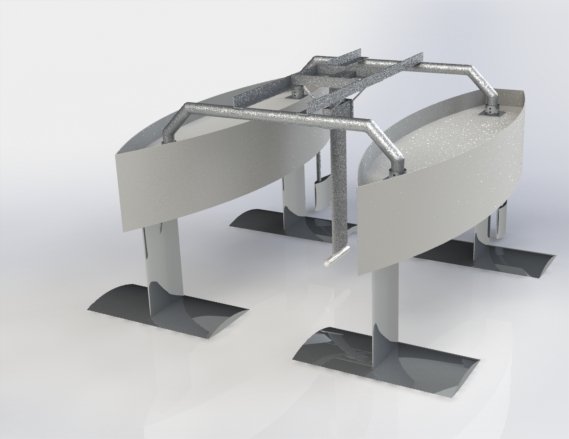

Each connections are bolted tightly to secure the hulls to the main structure. Waterproofing was done on each connection point to prevent the ingress of water into the hull of our boat. The metal frame is not merely bolted to the surface of the hull. It actually goes into the hull and act as a support for the boat.

As a result, we have a stable boat that is able to withstand the load of at least 3 grown man!!

The holes on the hulls are designed so that weights can be placed inside the hull for stability. While the built team is doing this, the electrical team is still figuring our the best electrical configuration for optimized speed and safety.

Hey guys, sorry for the late updates, last week, our controller board FINALLY arrived! Talk about rushed development cycle!

We have to figure our the operation of the board ASAP! It turns out, this board is so expensive for a number of reasons.

First of all, it supports different types of input, be it potentiometer, PWM, Serial, or even TTL logic. This makes it really versatile for different purposes. The manufacturer advertises it as being able to control planes, boats as well as cars.

To design the control system, we basically configure the board to receive PWM input from the RF receiver module. Normally, in an RC car, the PWM signals will be fed into an Electronic Speed Controller (ESC), which will in turn, control the main motor of the RC car.

For our case, this board is our ESC, and the signal from the RC module will be fed directly into the board.

Programming the board is relatively straightforward. There are several preset values for the boat which will be available for us to load into the controller. The settings are defined as memory 'banks', which contains settings optimized for various applications. For our case, we are modifying the settings with Bank_2 as our starting point.

Just a little update to our backers if you have not followed our blog yet. Swinsurfers is commited to designing an efficient boat which could potentially carry 200kg of weight and still travel fast. It does this by employing a T-shaped hydrofoil. A hydrofoil is like an aircraft's wing underwater. It works with the same principle: generating upward lift when there's a forward thrust. The lift have to be just right to cancel off the effect of the mass being transported. Too much lift, and the boat will end up flying out of the water and flip over. Too little, and the boat will not be able to 'fly' above the water. At the correct configuration, the hulls will be lifted out of the water, leaving only the hydrofoils in contact wil the water surface, thus, reducing drag, allowing us to 'surf' at greater speed.

We've added metal reinforcements to the front and back of the boat hull to withstand the force from incoming wave. Next step is to proceed to join the two boat hulls together to form a complete catamaran. Our hydrofoils will then be fabricated and attached to the boat.

The team here at Swinsurfers is SUPER EXCITED to be accepted as part of the MyStartr Community!!!!

The propeller and controller which we purchased earlier on is finally on the way here!! This would mean the boat can be assembled and tested pretty soon!